Circumferential and Bypass Seals

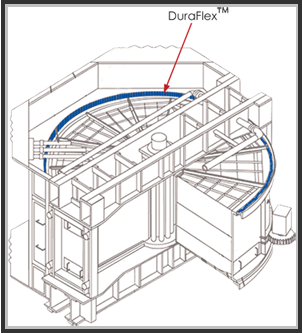

The DuraFlex ™ bypass or circumferential seal is engineered for rotary regenerative airheaters. The DuraFlex™ seal design increases the efficiency of the plant by reducing station fan power usage, increasing the thermal efficiency of the airheater and reducing the overall net heat rate of the plant. The circumferential seals prevent air and gas from bypassing the heating element through the space between the rotor and the housing shell. They are retained by mounting angles bolted to the circumference of the rotor. The circumferential seals wear against the sealing rings, which are welded to the housing of the air heater. The bypass seals are mounted on the housing and seal against the rotor-mounted T-Bars. Circumferential and bypass seals are equipped in the hot and cold ends of air heaters.

The DuraFlex™ high-performance circumferential and bypass seals use a patented revolutionary interlocking design. This technique reduces the air gaps normally found in other circumferential or bypass sealing systems. The DuraFlex™ circumferential/bypass seals have a unique design that contains two layers in one interlocking seal. This feature reduces the cost of seal replacement and installation time by half in comparison to standard circumferential/bypass seals. This product line has an unmatched track record in the industry; efficiency improvements have increased our customer productivity and significantly reduced fuel cost. The product quality is unsurpassed and customers report they last longer than any other sealing product available in the marketplace. This unique interlocked and reinforced design not only provides a tight seal, it is virtually immune to the problem of torn tabs commonly experienced with OEM style seals.

The bypass seals are mounted on the housing and seal against the rotor-mounted T-Bars. Circumferential and bypass seals are equipped in the hot and cold ends of air heaters.

DuraFlex™ – An Efficient Seal

The DuraFlex™ high-performance circumferential and bypass seals use a patented revolutionary interlocking design. This technique reduces the air gaps normally found in other circumferential or bypass sealing systems.

DuraMesh™ – For Bypass Seals

DuraMesh™ is a new idea to add to Paragon’s sealing solutions. DuraMesh™ is a stainless steel mesh cloth impregnated with “clay” that compliments the bypass seals at the air and gas inlet sides of the airheater. The DuraFlex™ Seal provides an edge free surface that prevents seal tabs from being torn loose in the event the rotor comes in contact with the seal or a foreign object such as a clinker becoming lodged between the rotor and the seal. With standard circumferential and bypass designs, it is very common for seal tabs to be torn away thus exposing large gaps, which provide paths for leakage past the airheater.

DuraMesh™ minimizes the bypass leakage found in rotors that have become warped and are no longer round. This out-of-round condition creates additional leakage due to the gap between the moving T-Bars and the DuraFlex™ Bypass Seal. (This can be larger than the contact portion of the seal and the sealing surface.) DuraMesh™ is set on top of the DuraFlex™ seal thus extending the sealing surface up to 4 inches to address this out-of-round condition. The mesh (double thickness) is set with a slight bend to accommodate the rotor type and shape. As the airheater heats up the cloth bends even more, however it is still kept in place by the pressure of the incoming air.

The structure of the material is a stainless weave of mesh with a silicone fabric and coated with an organic high temperature proofing to make it durable, flexible and very heat resistant. The temperature in service is up to 1,250 degrees Fahrenheit.

Product Features

The DuraFlex™ Seal provides an edge free surface that prevents seal tabs from being torn loose in the event the rotor comes in contact with the seal or a foreign object such as a clinker becoming lodged between the rotor and the seal. With standard circumferential and bypass designs, it is very common for seal tabs to be torn away thus exposing large gaps, which provide paths for leakage past the airheater.

The DuraFlex™ circumferential/bypass seals have a unique design that contains two layers in one interlocking seal. This feature reduces the cost of seal replacement and installation time by half in comparison to standard circumferential/bypass seals.

Product Design

The DuraFlex™ Technology is a patented and industry proven product line exclusively designed for customers seeking to maximize the efficiency and reliability of the airheater. This product line has an unmatched track record in the industry; efficiency improvements have increased our customer productivity and significantly reduced fuel cost. The product quality is unsurpassed and customers report they last longer than any other sealing product available in the market place.This unique interlocked and reinforced design not only provides a tight seal, it is virtually immune to the problem of torn tabs commonly experienced with OEM style seals.

DuraFlex™

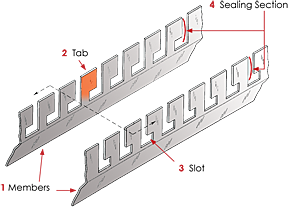

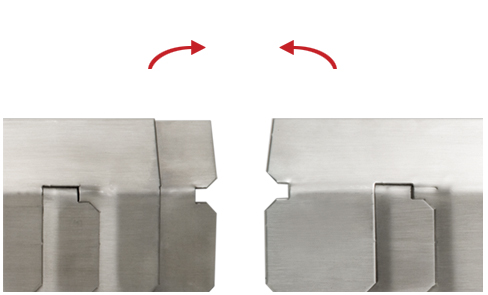

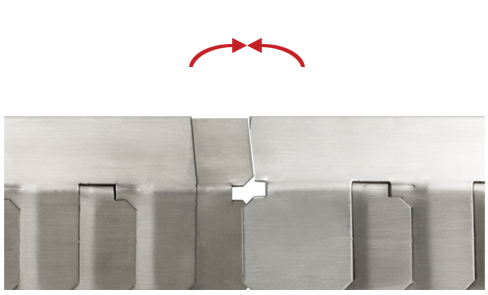

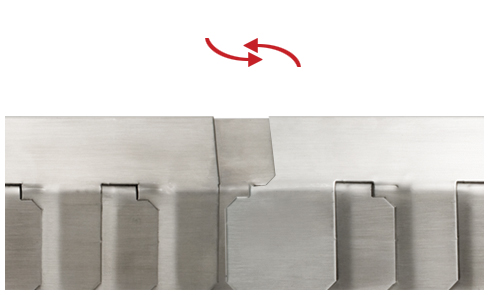

The DuraFlex™ seal has two interlocking members of specially shaped tabs and slots. The tabs on the first member are positioned through the slots of the second member to provide a very strong and seamless, yet flexible, high performance sealing system. The interlocking tabs tightly cover all of the slots thus providing a gapless seal section that dramatically reduces energy wasting bypass leakage. The seal is mounted either to the rotor or to the inner wall of the housing so as to extend through the bypass gap between the rotor and the inner wall of the housing.

DuraMesh™

DuraMesh™ minimizes the bypass leakage found in rotors that have become warped and are no longer round. This out-of-round condition creates additional leakage due to the gap between the moving T-Bars and the DuraFlex™ Bypass Seal. (This can be larger than the contact portion of the seal and the sealing surface.) DuraMesh™ is set on top of the DuraFlex™ seal thus extending the sealing surface up to 4 inches to address this out-of-round condition. The mesh (double thickness) is set with a slight bend to accommodate the rotor type and shape. As the airheater heats up the cloth bends even more, however it is still kept in place by the pressure of the incoming air.

The structure of the material is a stainless weave of mesh with a silicone fabric and coated with an organic high temperature proofing to make it durable, flexible and very heat resistant. The temperature in service is up to 1,250 degrees Fahrenheit.

When they sent their service engineer out, he helped us, and he had their best knowledge that helped us out in ways we never expected. He had 25 years in power generation.

BGE

BGEWe purchased contact seals from Paragon. They are the only company that had this type of seal. That is why we went to them. The standard seals were wearing out prematurely.

APS

APSThe planners tend to feel comfortable calling a Paragon person and discussing a plan and talking through recommendations. There is a valued relationship there.

APS

APSI value the strong relationship with Paragon that I have. They have been very customer oriented.

APS

APSVery happy with the in-field service. There is loyalty to Paragon, based on the in-field service.

Black Hills Energy

Black Hills EnergyThey have a very good crew that did the installation. They came in early. They knew what they were doing, and I didn’t have to stay out their constantly, and they kept me informed.

AES

AESYou get more of a personal care, because they are a smaller company. I work for a number of plants. I would and have recommended Paragon. I have that confidence.

Westar Energy

Westar EnergyCustomer service is the main reason for our loyalty. You always find things that are not planned for, so we need it flexibility and great service a lot during outages.

Westar Energy

Westar EnergyThe customer service is what makes them unique. That is it by far. Plus, you could also say having more innovative designs. Giving the customer more options than just OEM replacements.

Mirant

MirantParagon has better customer service. They are easier to get a hold of and really seem motivated to get you answers.

Mirant

Mirant“The biggest benefits from Paragon are a better after market product, and they help me prove to my management on what we are getting (pay for performance)

Mirant

MirantWhen they say something is going to happen, they deliver on it. Trust is really important. Less time for me worrying overseeing

Mirant

MirantWhen they say something is going to happen, they deliver on it. Trust is really important. Less time for me worrying overseeing

Mirant

MirantThe relationship is a little more collegial with Paragon than others. They are out to solve my problems with me. When they say something is going to happen, they deliver on it.

Mirant

MirantOnce you use Paragon’s seals, it is very clear that it is better. It just maintains the seals longer.

Midwest Generation

Midwest GenerationAll the technical guys, field reps are great. When I call they are available

Midwest Generation

Midwest GenerationI would call them a partner. They have the engineering background that the younger engineers here don’t have. I am buying a technical product. Their service engineering is just as important as their product.

Midwest Generation

Midwest GenerationWhat they said, they delivered. Meaning, they will stand by you if something goes wrong

Southern Power Company

Southern Power CompanyParagon earned our loyalty through the people first. When there was a problem they made it right. They have really good ideas and good service. And they stand behind their products.

Deseret Power

The Paragon technical supervisor provided was a real help to us on our project. We were pleased with his assistance and knowledge of our Ljungström pre-heaters. I’m keeping his and your contact information for any future shutdowns…

Adjoining the seals

Adjoining the seals Start of the interlock

Start of the interlock Full interlock position

Full interlock position